Occupant safety for military vehicles

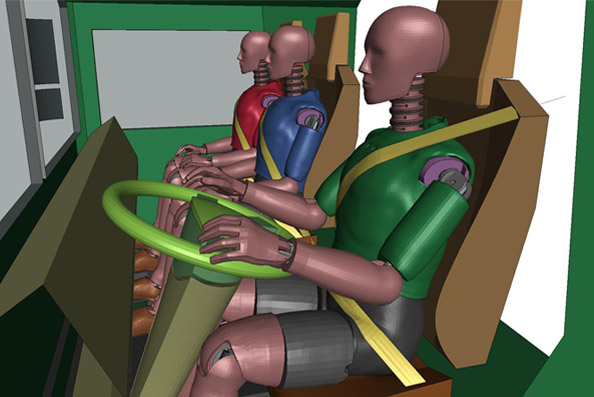

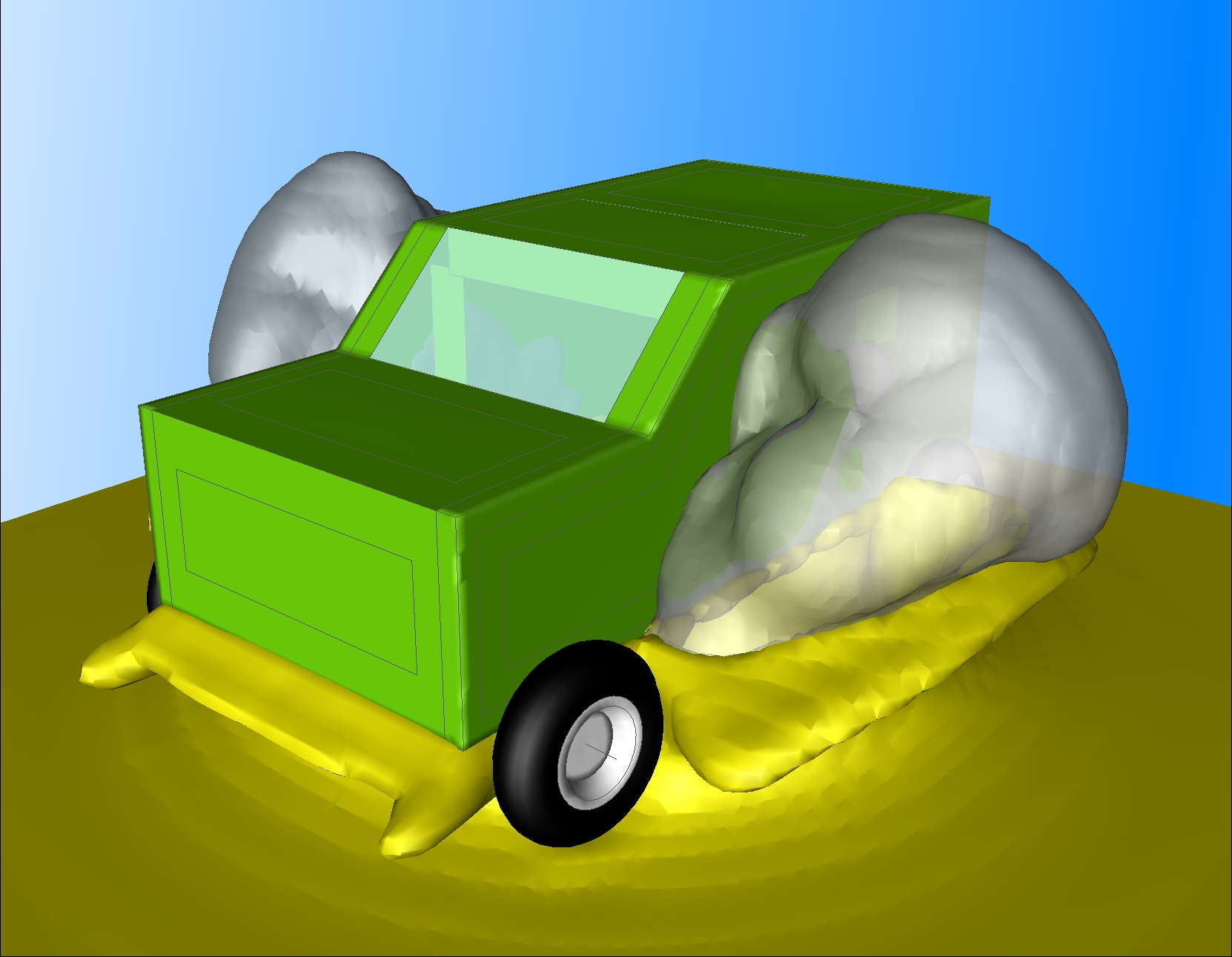

Fraunhofer EMI is researching how occupant restraint systems work in military vehicles.

Fraunhofer EMI is researching how occupant restraint systems work in military vehicles.

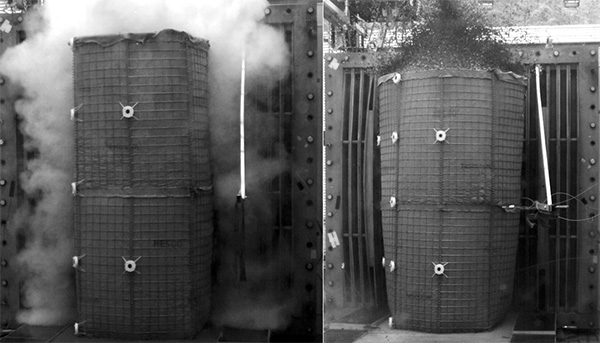

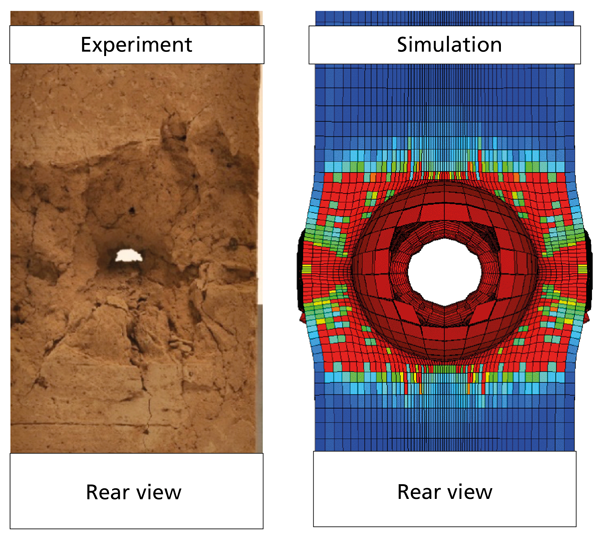

A new method makes it possible to precisely calculate the damage to concrete under heavy loads, including breakage and debris formation. It analyzes individual pieces of debris and precisely determines their trajectories.

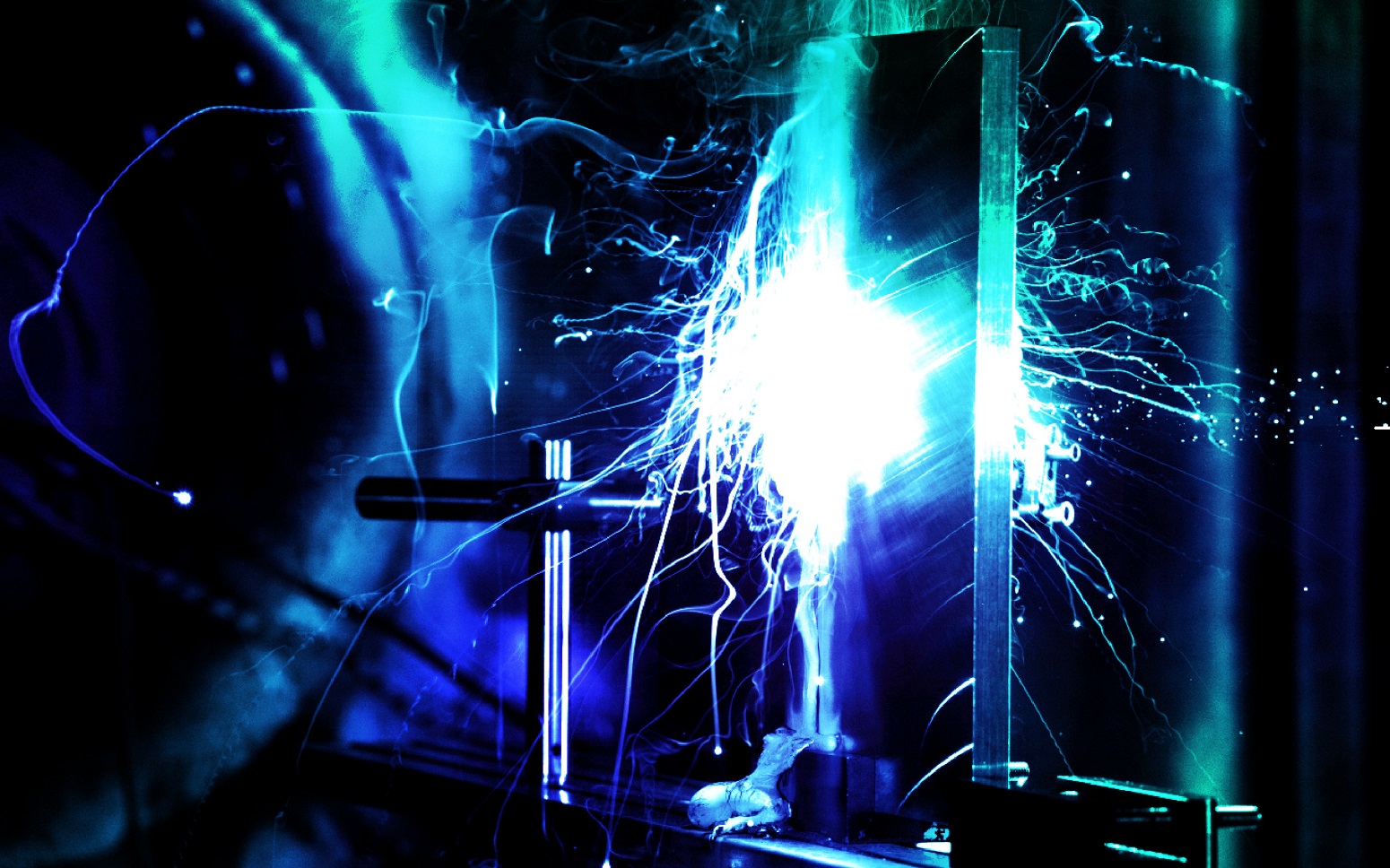

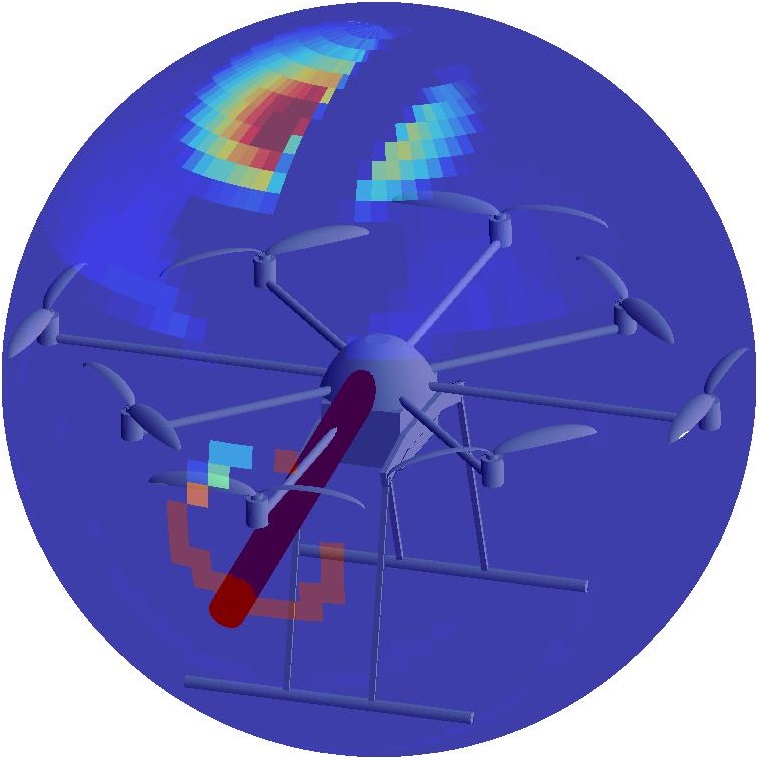

Fraunhofer EMI is developing powerful software that simulates complex laser-matter interactions and evaluates the effects of laser weapons.

A software tool developed at Fraunhofer EMI optimizes safety distances, storage capacities and cost planning for the German Armed Forces.

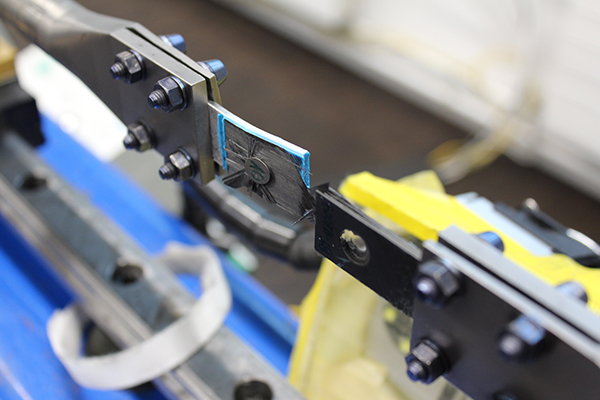

Using light-gas guns to research defense mechanisms against new types of hypersonic threats.

How Fraunhofer EMI uses algorithms and simulations to better protect critical maritime infrastructure.

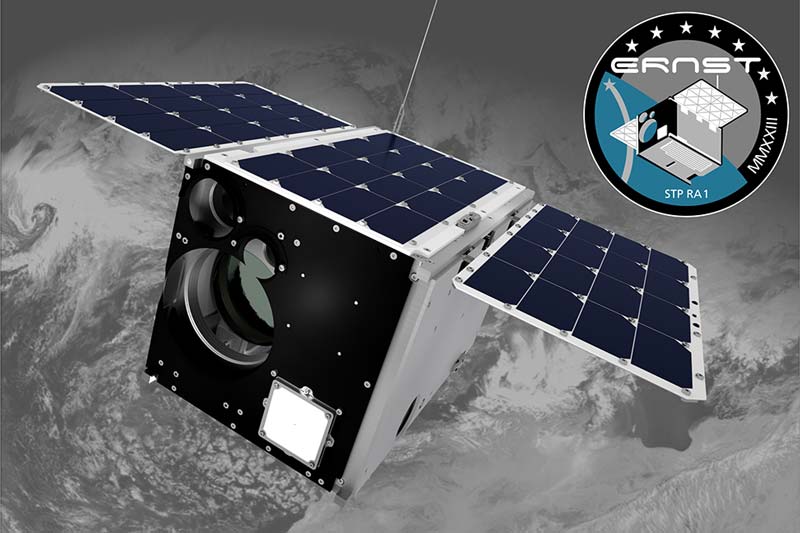

ERNST demonstrates the potential of small satellites for military applications. Using innovative infrared technology, it improves missile early warning and provides important infrared data for the national security strategy.

National and international agreements to reduce greenhouse gas emissions and the increasingly limited availability of traditional building materials are forcing the construction sector to turn to alternative, more sustainable building materials and construction methods.

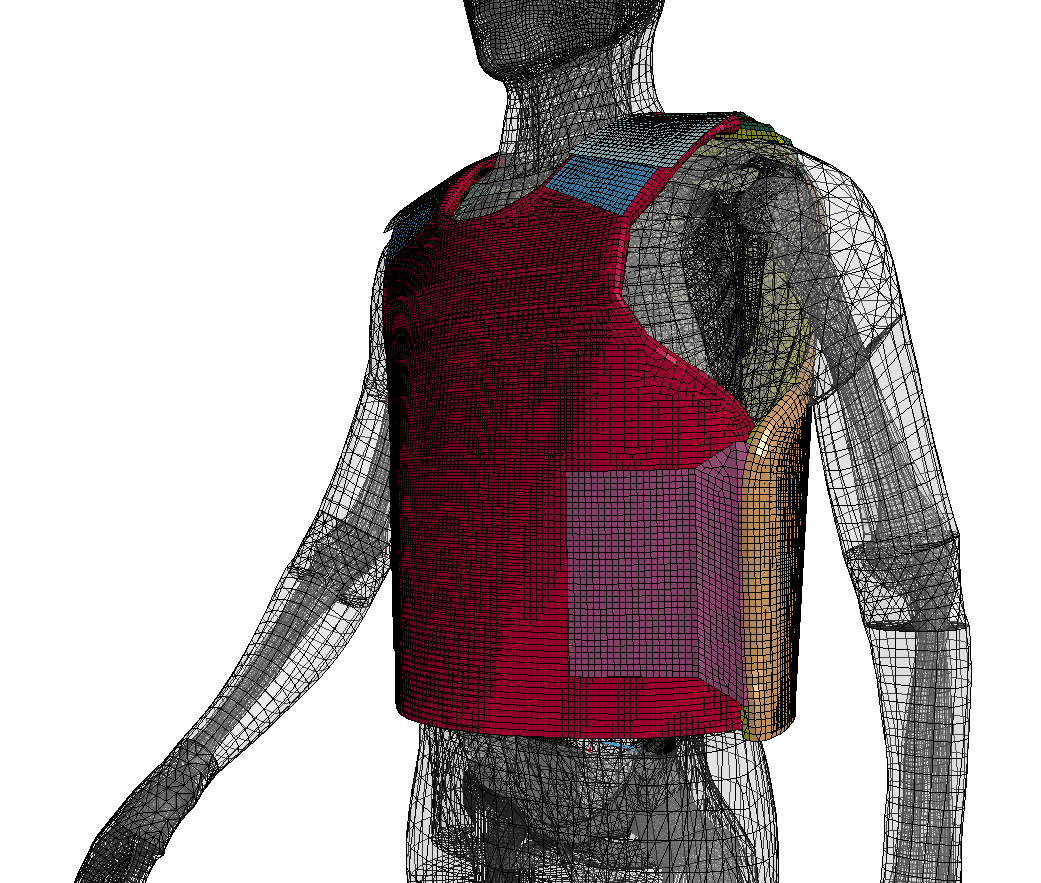

Injuries caused by deformation of protective equipment

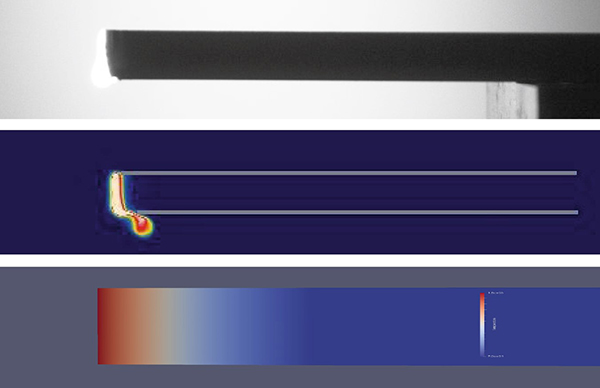

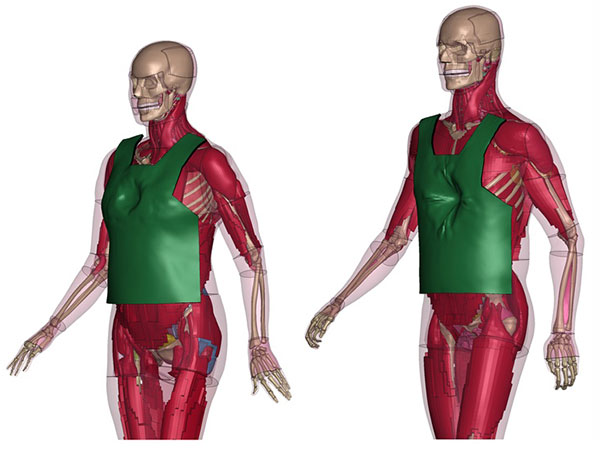

Behind Armor Blunt Trauma (BABT) is caused by non-penetrating ballistic impacts caused by the rapid deformation of personal protective equipment (PPE). During the impact, the PPE and the underlying body tissue deform rapidly. This highly dynamic load can cause bruises, tears, fractures and injuries to organs.

How Fraunhofer EMI uses generative algorithms to create efficient engineering designs and solve complex design problems.

The capabilities of weapon systems designed for use in dynamic deployment scenarios cannot be fully investigated in purely static test scenarios.

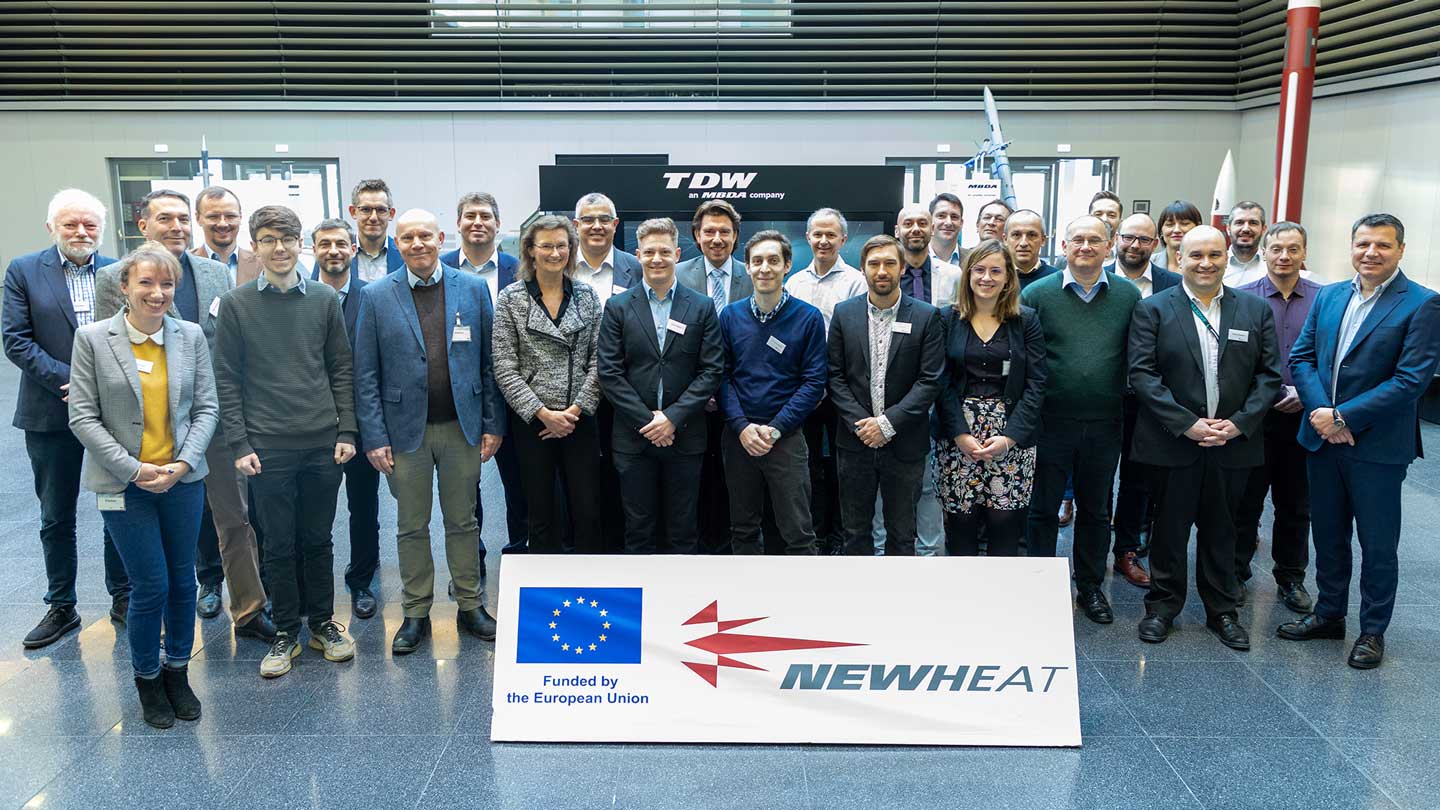

Fraunhofer EMI contributes to the NEWHEAT project by bringing in its competences in the field of material testing and modeling, as well as numerical simulation of projectile-target interaction. Within the framework of the European Defence Fund (EDF), which was proposed by the European Commission in 2018 and approved by the European Parliament in 2021, common capabilities in the field of defense technology are being built up with European partners.

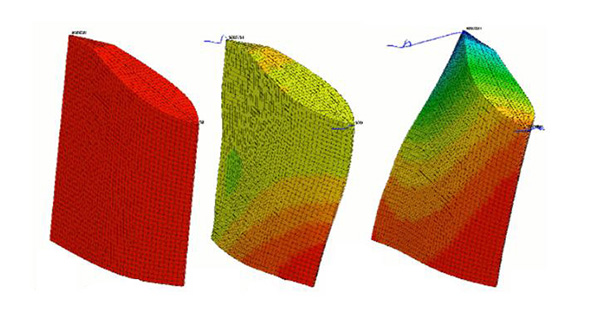

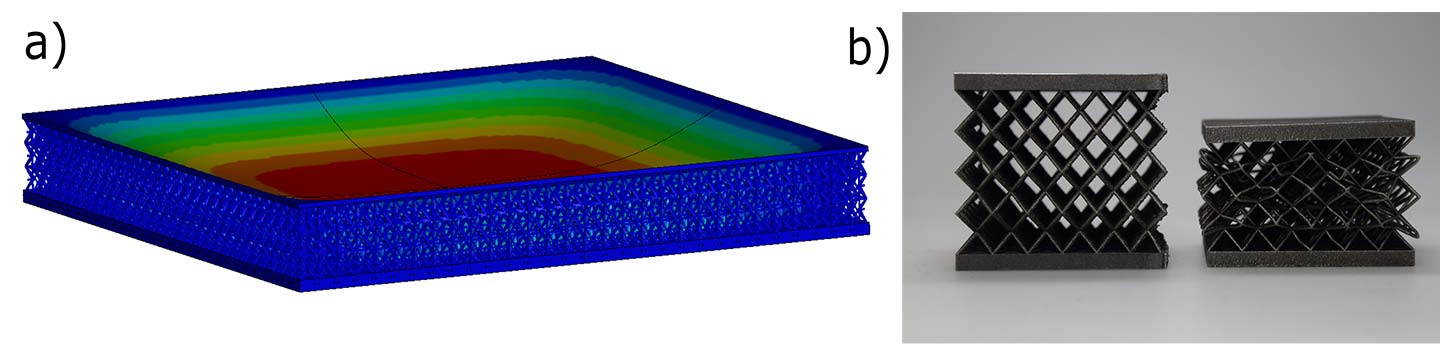

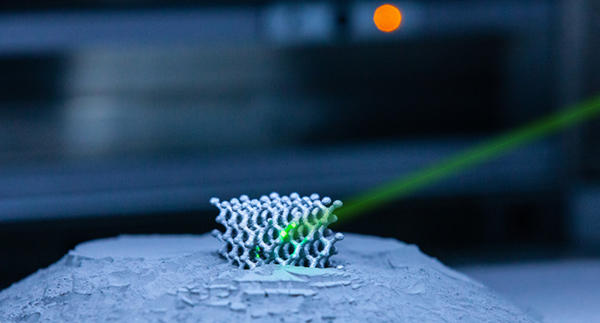

While the impact of a projectile causes a very localized material stress, the impact of an explosion usually results in a planar material load. In high-speed dynamics, it is generally of great importance to be able to design materials and structures that are capable of absorbing energy while still offering a high residual load-carrying capacity. Metallic 3D printing allows a high degree of design freedom, and especially locally adaptable lattice structures appear to be particularly suitable due to their lightweight construction. To find an optimal design of these complex structures, the use of machine learning and evolutionary algorithms in combination with numerical simulations is being explored.

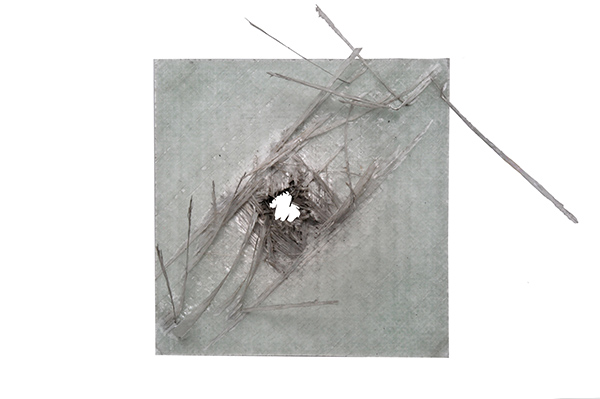

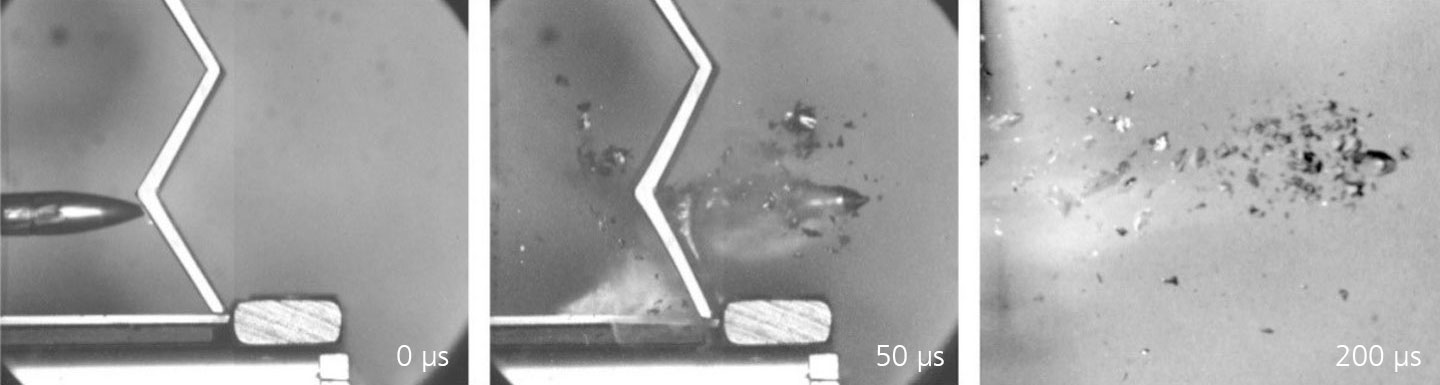

Principles of lightweight protection such as the destruction of the projectile core are of fundamental interest for lightweight protection. Particularly in terms of flexibility and adaptability, protective structures can benefit if they can be manufactured using metallic 3D printing processes. Fraunhofer EMI is conducting research into suitable materials and structural configurations for this purpose.

Because of their ability to adapt to geometric constraints, 3D printing processes could also be beneficial. For example, when protecting components of robotic systems used to support soldiers. The following is an example of how the simultaneous use of the effects of spacing and inclined surfaces can enhance the ballistic protection.

In the future, autonomously navigating robotic systems will make it possible to support soldiers directly in the field. Fraunhofer EMI has participated in and coordinated the international ARTUS research project.

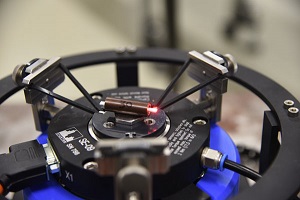

Demonstration of a small, standardized, low-cost satellite in an ambitious mission

With its research project to build a small satellite platform and prepare a mission to investigate potential applications for threat detection, Fraunhofer EMI is making its first substantial contribution to the new capability dimension of space. With the completion of the ERNST flight model, the first small satellite mission for the German Armed Forces is imminent. ERNST is a 12U CubeSat equipped with a cryogenically cooled infrared imager for demonstrating the potential of small satellite technology for military purposes while providing knowledge on early detection of ballistic or hypersonic missiles from low Earth orbit.

Fraunhofer EMI is investigating how live firing exercises can be made more modern and efficient by using sensor technology and methods of digitalization. The challenge is to ensure safety while meeting advanced requirements.

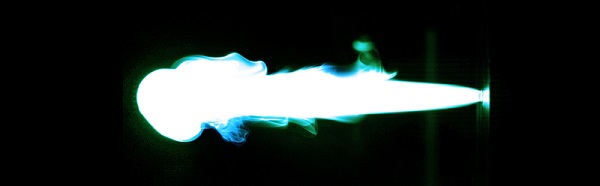

With the progress in laser technology, compact and efficient laser systems have become available for some years, which combine high output powers of several 10 kilowatts with a very good beam quality and can therefore be focused even over long distances. This will enable future military applications. Various nations are currently investigating the potential of such laser systems as an effector for a laser weapon. Experts assume that the further development of the technology will enable an output power in the 100-kilowatt class.

Metal matrix composites (MMC) consist of a metallic matrix that contains a second material, for example in the form of fibers or particles. By combining the materials, MMCs can join the advantageous properties of the two components or even achieve better mechanical parameters than the individual materials alone.

Lithium-ion (LI) technology is nowadays indispensable in both military and civil environments. Their use ranges from battery packs for portable electronics to vehicle batteries and large stationary storage systems. Fraunhofer EMI researches to improve the safety of these batteries and carries out experimental tests with a focus on dynamic load cases (for example, the crash behavior of batteries).

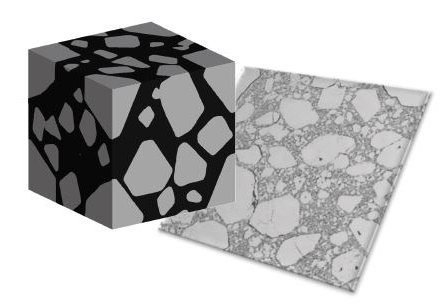

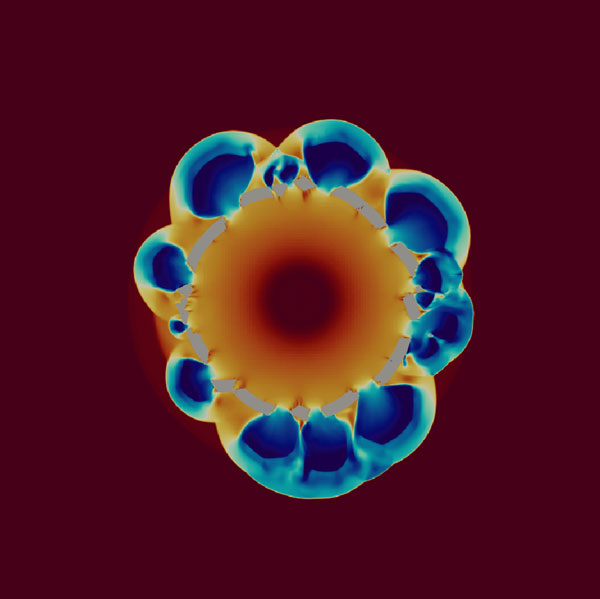

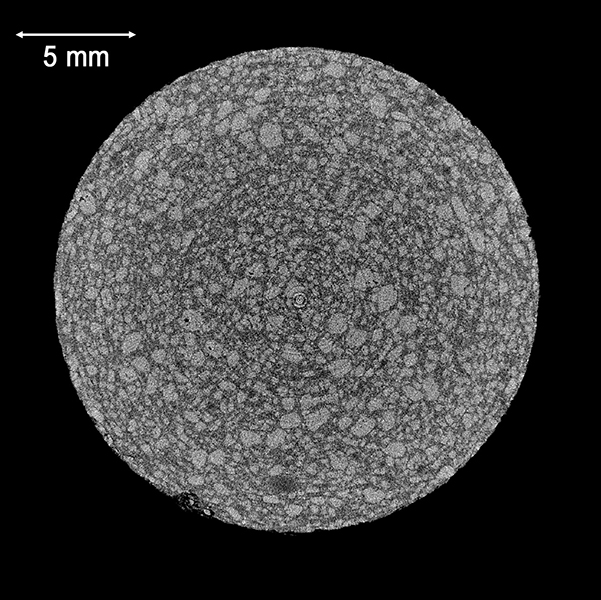

The application of hydrocodes for the simulation of initiation processes in plasticbonded explosives (PBX) on the mesoscale is a challenging task. The thermo-mechanical behavior of the material shall be predicted, including possible initiation. For this purpose, EMI uses its own, highly specialized software SOPHIA, which is continuously further developed and improved.

Up to now, virtual human body models have mainly been applied in applications where clothing does not play a significant role, for example, car-to-car or car-to-pedestrian simulations. The Human Body Dynamics Team of Fraunhofer EMI has developed a method to put on a soft ballistic vest to a virtual human body model in a standing posture.

Military aircrafts are subjected to very high-rate loading, as for example high-velocity impacts or blast loads. In order to design safely these types of structures, it is important not only to characterize the materials but also the joints connecting the different parts.

Soil-filled gabions can provide effective protection against shock waves resulting from detonation events. Therefore, the group Security of Structures is researching the potential of these structures as protective enclosure in order to design them as a wall system safe and efficient against hazards like blast loads.

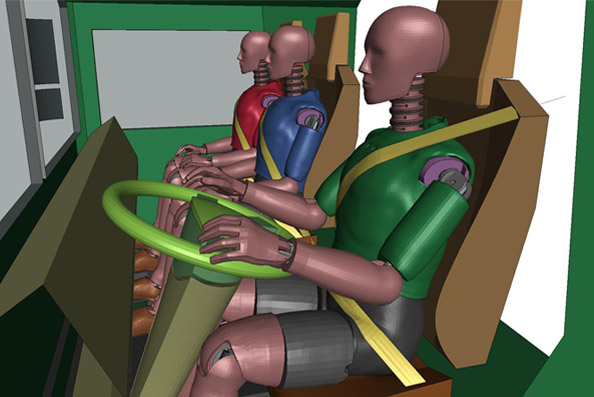

Fraunhofer EMI has now got significantly expanded experimental capabilities to examine the effects of high-intensity laser radiation and scaling effects at short distance in the laboratory. Basic research can now be extended up to a power of 120 kilowatts.

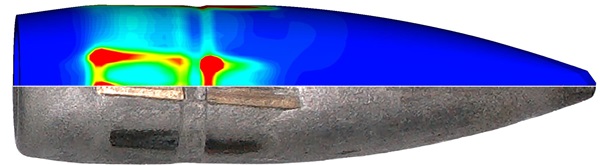

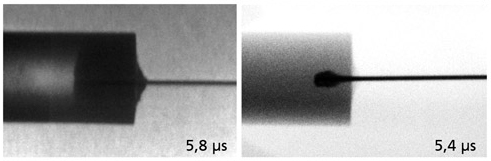

The accuracy of weapons is largely determined by the mechanical interaction between the barrel and the projectile during launch. Barrel vibrations and lateral oscillations of the projectile perpendicular to the barrel axis cause variations in the bullet’s motion state after muzzle exit, resulting in a dispersion of target impact locations.

The detonation of IEDs (improvised explosive devices) can cause high impulse transfer into vehicles in operation and thus endanger the occupants. In the department Experimental Ballistics, scientific methods are being developed to better protect land vehicles against IEDs.

The aim of the Fraunhofer lighthouse project “eHarsh” is the development of a technology platform intended for the design and manufacturing of sensor systems for the application in extreme harsh environments.

Co-simulation is a computational approach that enables the simulation of a system through parallel and coupled simulation of its parts. At Fraunhofer EMI, simulation methods are developed which permit the co-simulation of fluid structure coupled systems. These methods are particularly suited for the analysis of explosively loaded engineering structures.

For the enclosure of protective zones, simple but effective solutions are needed that protect individuals and material against extreme events, e.g. detonations. Basket systems, which can be filled with soil available on-site, are often used in this context.

Handguns are usually made up of the subsystems weapon, ammunition and rifle scope, all of which are produced by different manufacturers. In combination, these subsystems have to fulfill the requirements imposed by the German Federal Armed Forces (Bundeswehr) in various environmental conditions.

Modern ammunitions are usually based on polymer-bonded high explosives (PBX). Fraunhofer EMI studies how these phenomena can be included in the material modelling of PBX.

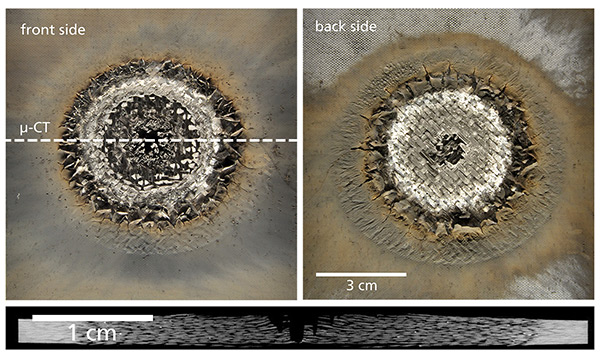

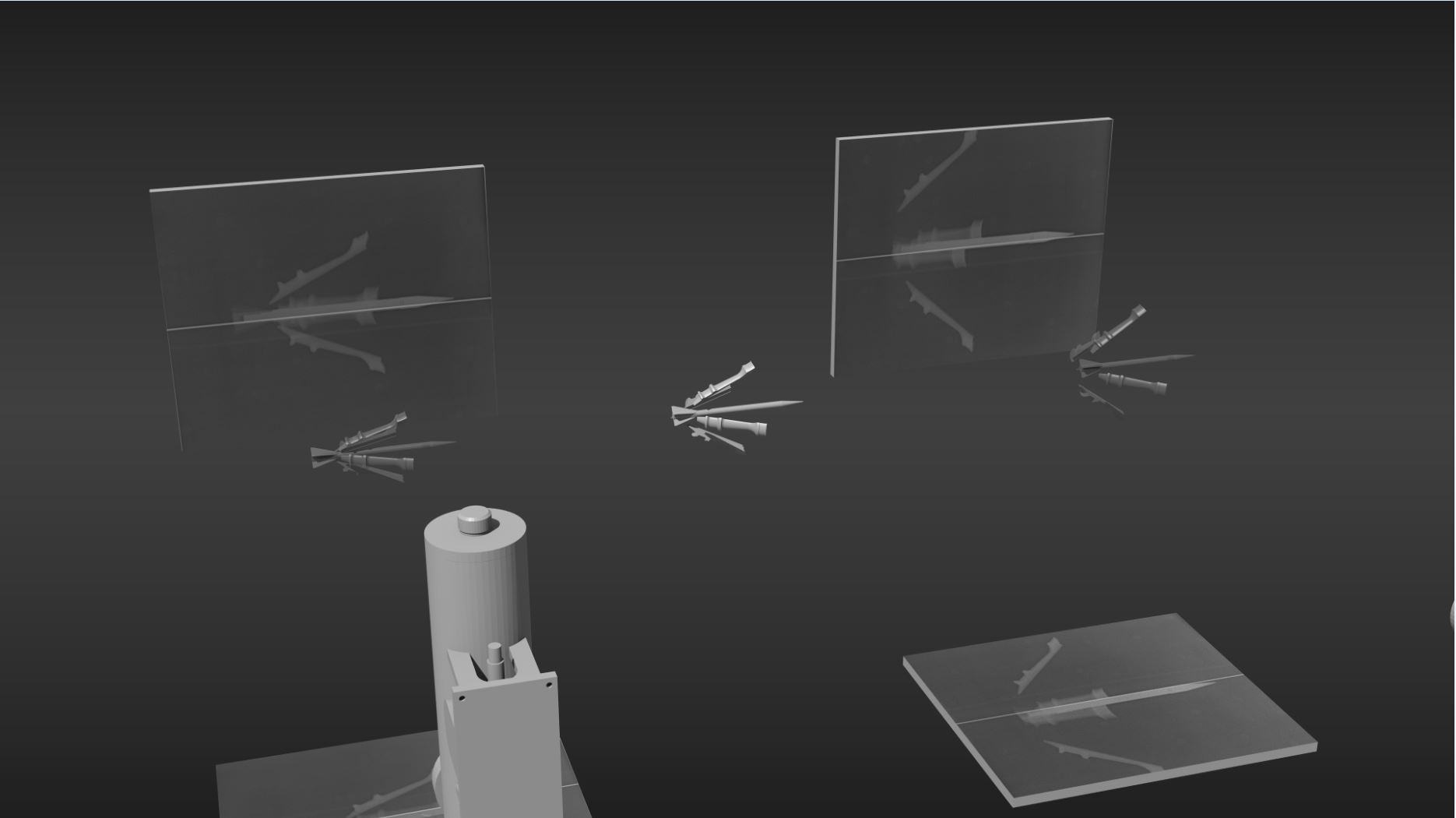

In order to be able to describe the interaction between the pre-damaged glass and the projectile, Fraunhofer EMI develops methods to pre-load glass in a defined way using planar plate impact to detect and analyze the damage quantitatively via X-ray tomography, and to determine the strength properties.

For an application of high-power lasers, it is necessary to analyze in detail the laser propagation and to identify potential threats by laser radiation. For this purpose, Fraunhofer EMI develops the safety analysis tool LSQRA (Laser Safety Quantitative Risk Analysis) for 3D-visualization of simulated operational scenarios with laser effectors.

The launch of military operations in conflict areas commonly implies the consideration of complex safety and security issues for soldiers onsite. One of these issues is related to the assessment of explosive events in build-up areas and the corresponding potential consequences for structures and inhabitants of these structures. Typical problems that need to be resolved are the definition of safety ranges around an ammunition storage in field camps and the assessment of deliberated attacks with explosives in urban areas within the context of a military operation in urban terrain (MOUT).

For the investigation of transitional ballistics of sub-caliber projectiles, an innovative, X-ray based measurement technique was developed which opens up new possibilities of examination.

High-strength steels are used in order to protect passengers from gunfire. During impact of a projectile, complex loading conditions, such as tensile and compressive loads but also bending and shear stresses, occur, e.g. depending on the angle of impact. At EMI, material tests are carried out with a special multiaxial test bench in order to reproduce such loads in the laboratory.

The powder bed based Laser Beam Melting (LBM) process allows the manufacturing of individual, lightweight and robust geometries. At Fraunhofer EMI, we have developed our own manufacturing parameters for the processing of materials used in defense technology. We have shown that even materials such as tungsten, which are difficult to process, can be additively generated in a high quality.

The spectrum ranges from new applications in security research to military applications and examinations of the processes in geological materials during meteorite impact.

Fraunhofer EMI is currently setting up a new laboratory for applications in laser technology featuring powerful lasers, in which novel pulsed laser applications as well as continuous-wave (CW) laser applications can be developed and tested.

The missions of the German Armed Forces (Bundeswehr) have raised new questions regarding the ballistic protection of building elements and building materials. In this context, for example, the evaluation of the protective properties of masonry is of great interest in order to ensure the protection of civilian population and deployed soldiers in the areas of operation.

Fraunhofer EMI uses laboratory accelerators to conduct impact experiments under laboratory conditions. By means of single-stage accelerators, velocities of up to three kilometers per second can be reached. Read more

In order to improve the protective effectiveness of armors it is crucial to understand the failure mechanisms of protective materials. Read more

During high-speed dynamic processes, deformations and strains are not immediately transmitted to the whole body of the impacted object, e.g., a cylindric rod, once it is impacted at one end. Read more

For analyzing the damage propagation in glass, a detailed understanding of the occurring physical mechanisms leading to damages is crucial. Read more

Even at relatively small impact velocities, the maximum loads of materials under impact processes are already exceeded which leads to material failure. Read more