Mechanical material models for polymer-bonded high explosives

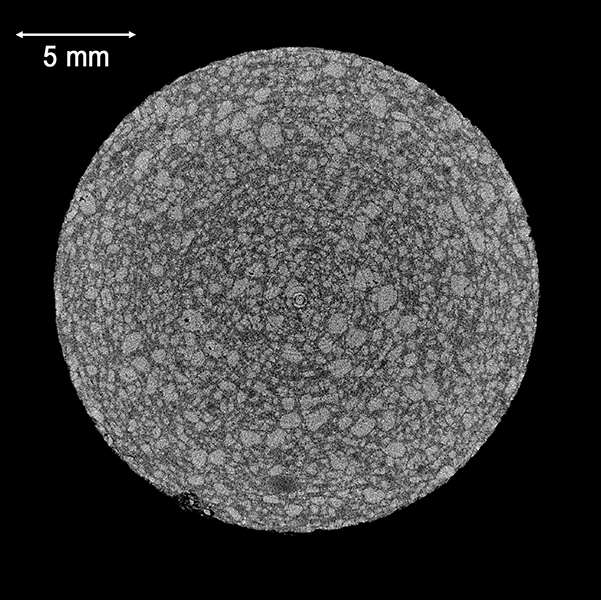

Modern ammunitions are usually based on polymer-bonded high explosives (PBX). These explosives are heterogeneous materials whose actual reactive components (such as octogen or hexogen crystals) are embedded in a polymer matrix. This composition determines the special mechanical properties of PBX. Crystals are characterized by high stiffness and brittleness, while the polymer matrix shows a typical viscoelastic behavior. Furthermore, the bonding of the matrix to the crystals plays a decisive role regarding the mechanical behavior and possible reaction mechanisms under dynamic loading.

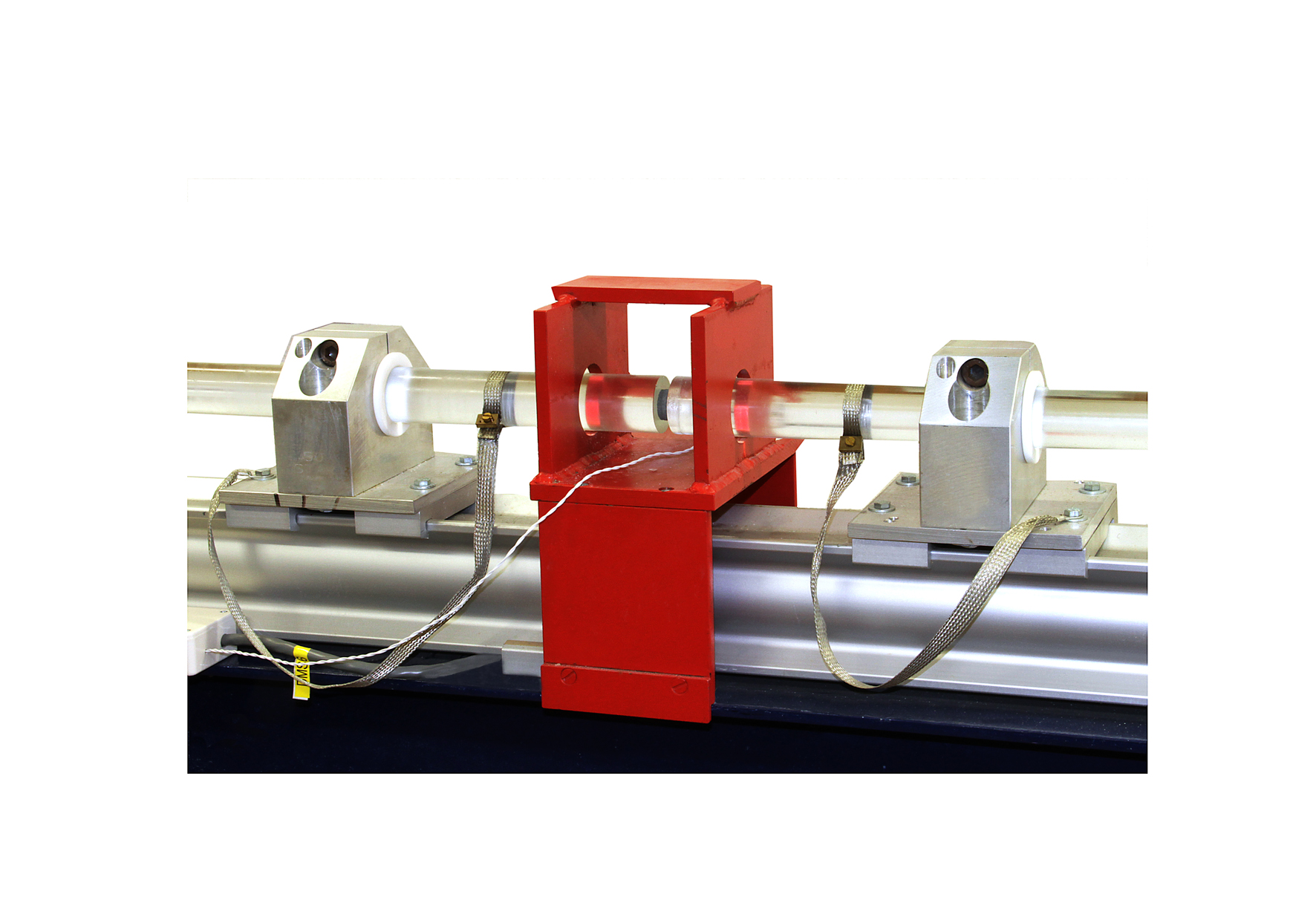

Fraunhofer EMI studies how these phenomena can be included in the material modelling of PBX. Currently, material models are used that combine viscoelastic behavior with crack formation processes, and thus are suitable for describing debonding phenomena between crystal and matrix. For the determination of the material parameters, Fraunhofer EMI has developed the corresponding experimental facilities. Besides a hydraulic press for the realization of high compressive loads, a split Hopkinson pressure bar for highly dynamic loads is employed. The derived material models are used for the evaluation of safety aspects during deployment and operation of ammunitions.