Restraint systems for maximum occupant protection

Fraunhofer EMI develops solutions that optimize restraint systems and improve occupant protection through experimental technologies and precise simulations.

Fraunhofer EMI develops solutions that optimize restraint systems and improve occupant protection through experimental technologies and precise simulations.

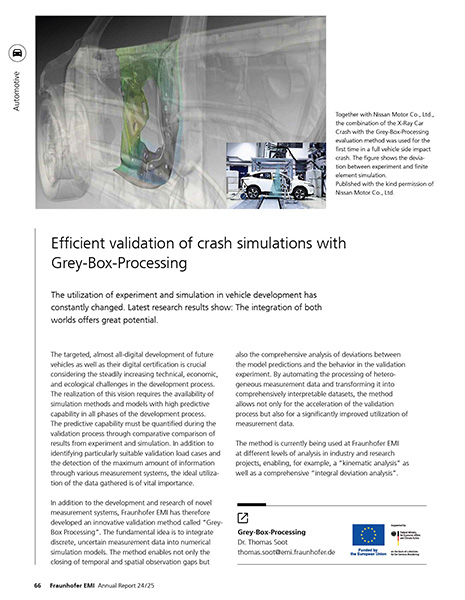

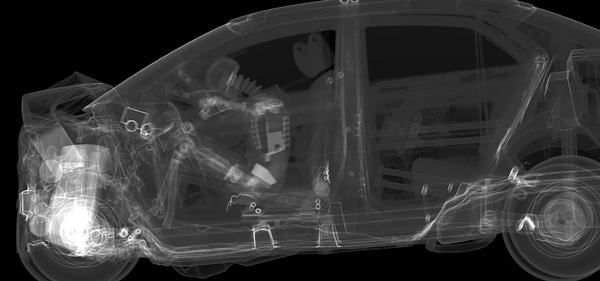

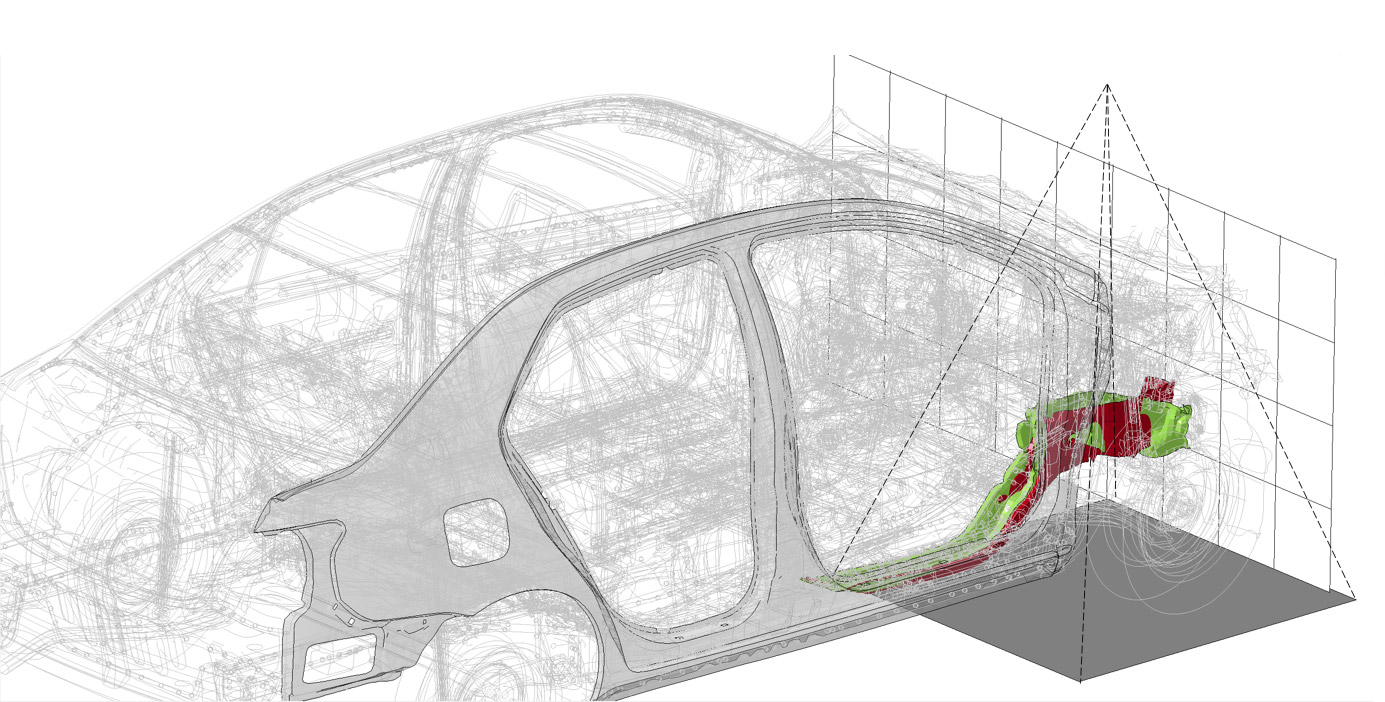

Together with Nissan Motor Co., Ltd., the combination of the X-Ray Car Crash with the Grey-Box-Processing evaluation method was used for the first time in a full vehicle side impact crash.

You can find a summary of the research in the current annual report on page 66.

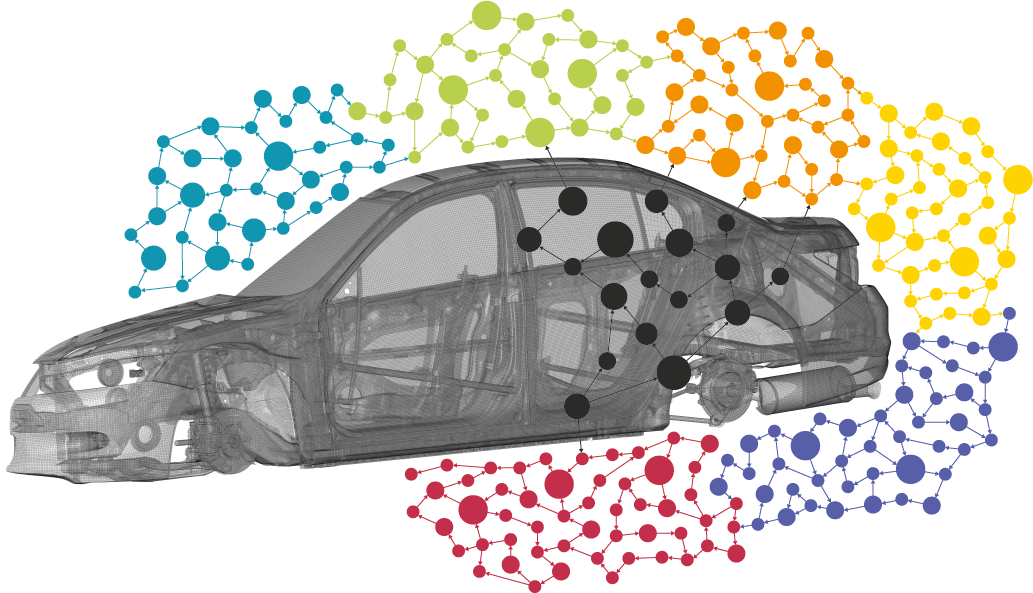

Fraunhofer EMI is researching the application of generative artificial intelligence in order to make data and the knowledge it contains usable for the design of vehicles in the long term.

One third of road fatalities are pedestrians. To improve their safety, Fraunhofer EMI is developing traffic simulations that integrate detailed pedestrian models for the first time.

The application of machine learning creates new material models that can be used to design structures more safely and sustainably.

The KIsSME project shows how innovative algorithms can filter out the critical moments in traffic from huge mountains of data, advancing research and technology while conserving resources.

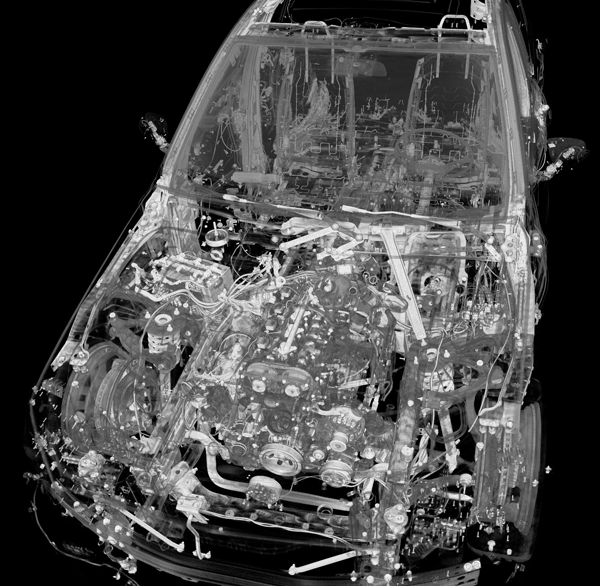

Together with Mercedes-Benz, Fraunhofer EMI has carried out the world’s first X-ray crash – with 1000 X-ray images per second.

The goal of the ATTENTION project is to develop a method for real-time injury prediction of vulnerable road users (VRUs), such as pedestrians or cyclists. For this purpose, data-driven methods are used to determine a situation-specific injury risk from vehicle-based video data and virtual tests with the help of digital human models. Prospectively, injury prediction enables both safe and efficient traffic through automated vehicle risk mitigation strategies.

Collecting the most relevant data is fundamental for further developing and validating autonomous driving functionality.

The basis for assessing autonomous vehicles are extensive data from traffic scenarios. To create such a basis is one goal of the AVEAS project, which is funded by the Federal Ministry for Economic Affairs and Climate Action.

Consisting of 26 funded and 2 associated partners from industry and science, the DigiTain research project started on January 1, 2023, with a total duration of 36 months. In DigiTain, processes, methods and models for fully digital product development and certification of sustainable electric drive architectures are being developed and tested using a technology demonstrator.

Component tests are expensive and time-consuming. Therefore, those tests should be performed in such a way that a maximum benefit out of the measured data can be achieved.

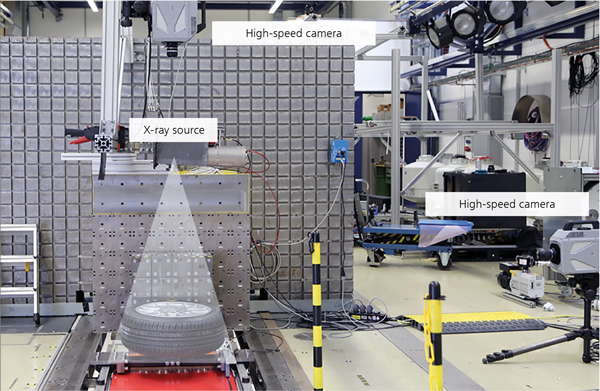

Car wheels might be subjected to severe loading and play an important role in safety, especially in frontal load case such as small-overlap. At Fraunhofer EMI, the world’s first X-ray images of wheels during a crash have now been produced as part of a student research project. The experiments were carried out in a specially designed setup at the Crash Center of the Fraunhofer-Gesell-schaft at the Efringen-Kirchen location of EMI. This way, spectacular images were created.

The aim of the ATTENTION project is to develop a method for predicting injuries to vulnerable road users (VRU) such as pedestrians or cyclists in real time. Fraunhofer EMI will contribute to the development of the collision and injury database as part of the ATTENTION project and focuses on VRU-car-impact simulations.

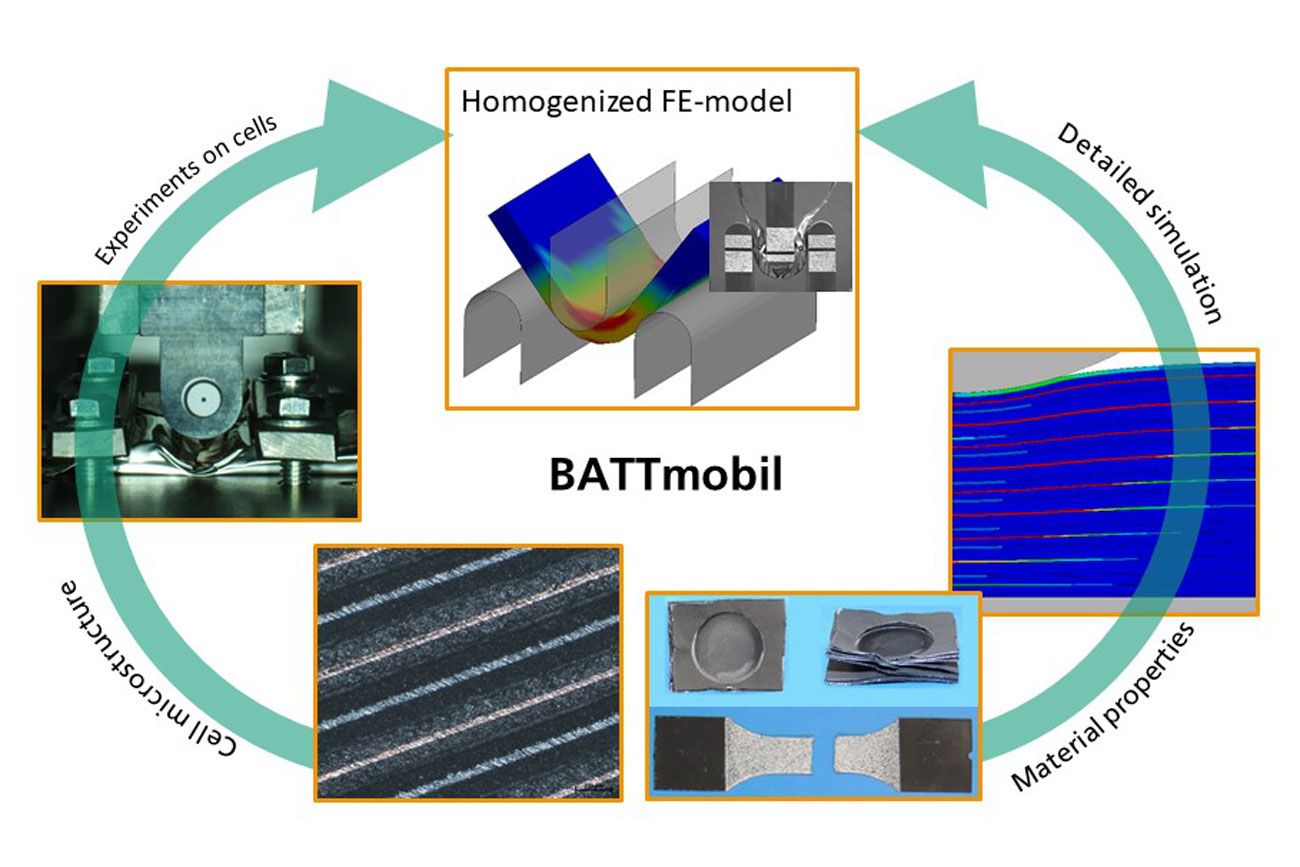

Batteries play the key part for crashworthiness of electric vehicles. It depends on their integrity whether an accident will cause damage comparable to conventional vehicles or a vehicle fire or even an explosion will occur. The latter are the consequences of overheating of the battery (thermal runaway), which may be caused, for example, by a short circuit triggered by the destruction of the internal cell structure. Therefore, a deeper understanding of possible cell deformations and their evaluation in relation to the occurrence of a short circuit is necessary to assess crash safety. As part of the BATTmobil project funded by the State Ministry of Baden-Wuerttemberg for Economic Affairs, Labour and Tourism, Fraunhofer EMI and Fraunhofer IWM have investigated these key aspects of battery safety. The project was successfully completed in October 2020 and is part of the Tech Center i-protect.

Wheelcharity – we get wheelchair-user protection rolling!

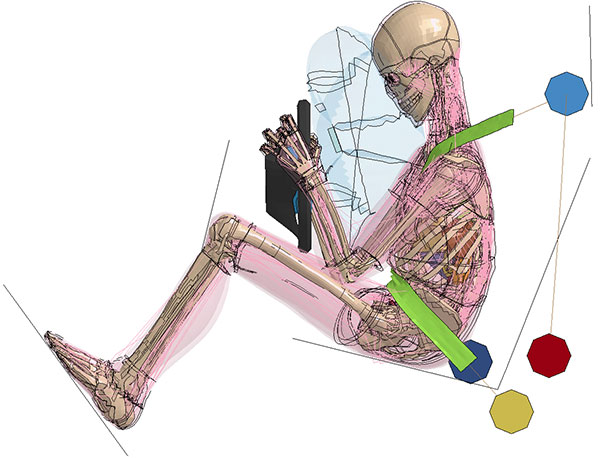

The multi-member team of Wheelcharity was funded as part of the FastTrack initiative of Fraunhofer EMI. The objective of the project is to gain insights into crash behavior of wheelchair users (WCUs), to identify possible risks of injury and to point out optimization potentials and to test them exemplarily for application.

Euro NCAP MPDB test deploys X-ray diagnostics and computed tomography: Fraunhofer Institutes EMI and IIS/ERZT carry out tests together with ADAC and Kistler Instrumente GmbH.

Imagine a typical accident scenario on a country road: Two vehicles at medium speed meet in a frontal crash. In most collisions of this type, the actual impact touches only a certain area of the vehicle front, not the vehicle in its full width. The effects of such a head-on crash are simulated in the crash laboratory. The test configuration presented here is based on the Euro NCAP MPDB test (mobile progressive deformable barrier), which was introduced in 2020 and uses an overlap of 50 percent.

The protection of vulnerable road users (VRU) is a critical aspect of road safety. Consumer protection organizations have already established guidelines for the sake of VRU protection, which govern the development of new vehicles and, up to now, mainly concentrate on pedestrians and cyclists.

The continuously increasing requirements on future vehicle systems regarding safety, costs, development times and the environmental impact lead to growing challenges within the automotive development process. To overcome these challenges, the continuation of the digitalization and virtualization of the development process is of vital importance. A reliable virtual vehicle development calls for simulation methods and models, which are optimized and validated based on the results of few real-world experiments.

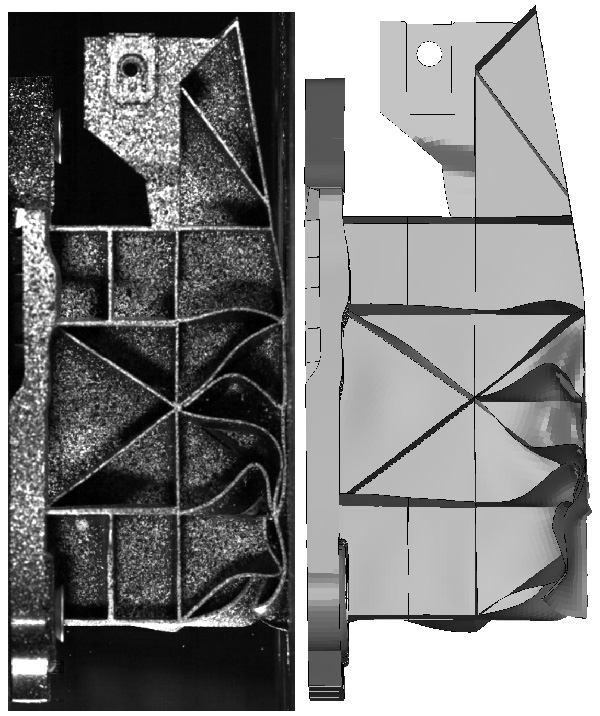

Using X-ray technology enables the obser-vation of the dynamic behavior of hidden vehicle structures under crash conditions. In addition to novel measurement technol- ogy, necessary algorithms for analysis and evaluation are developed within the scope of industrial and research projects.

In the light of digital transformation and increasingly data-driven research approaches, it is an essential goal to address the entire life cycle of research data and to sustainably exploit the data in versatile ways by the consistent implementation of the FAIR guiding principles (FAIR: findable, accessible, interoperable, reusable). The purposes of digital data management, which builds upon semantic technologies, include maximizing the added value from research data.

A big step towards the X-ray crash test has been taken: With the linear accelerator LINAC, EMI is equipped with a radiation source with which all materials commonly used in automotive manufacturing can be X-rayed. The short X-ray pulse duration allows tracing deformation processes that occur during a crash.

At Fraunhofer EMI, research to improve the crashworthiness of utility vehicles is conducted.

A car crash often happens very suddenly. Nevertheless, occupants are sometimes prepared – they see the crash coming and react accordingly: they contract their muscles, fully apply the brakes and brace against the steering wheel. With virtual human models, muscle stiffness can be simulated in different degrees, which allows making realistic statements regarding injury risks. Simultaneously, such models help to improve the safety of automobiles.

Up to now, the exact deformation processes taking place deep inside car structures during crash remained hidden. Using the X-ray Car Crash (X-CC) technology, the possibility of observing the said dynamic behavior of hidden structures under crash loading is investigated at the crash center of Fraunhofer EMI.

X-raying is an established material research technology, which in the industrial sector has thus far been restricted primarily to static and quasistatic analyses. With the X-CC technology, Fraunhofer EMI combines X-ray technology with highly dynamic deformation processes under crash conditions and thereby contributes to the overall understanding of the behavior of inner car structures during a crash. Read more.