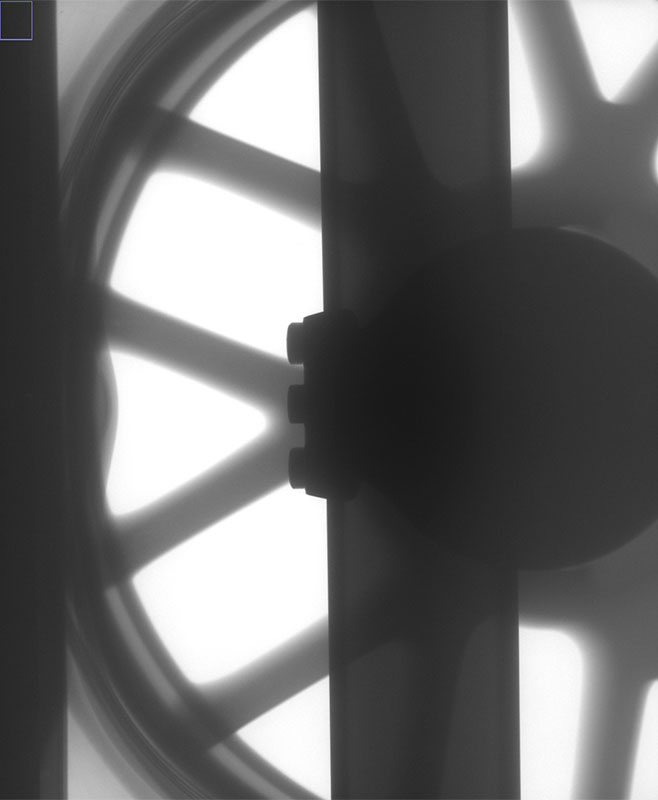

Within the scope of the student research pro-ject of Benjamin Schütz, a test setup for wheel tests was designed at the Crash Center of the Fraunhofer-Gesellschaft in Efringen-Kirchen for taking X-ray images. These recordings are the world’s first X-ray images of car wheels at the moment of crash.Dr. Malte Kurfiss, supervisor of the work, declares, “With such recordings we get a lot of attention in the professional community. The OEMs (original equipment manufac-turers) have a strong interest in observing hidden structures during crash in order to further optimize vehicle safety. Some cus-tomers are already waiting in line for our new X-ray source, a linear accelerator, to go into op eration.”

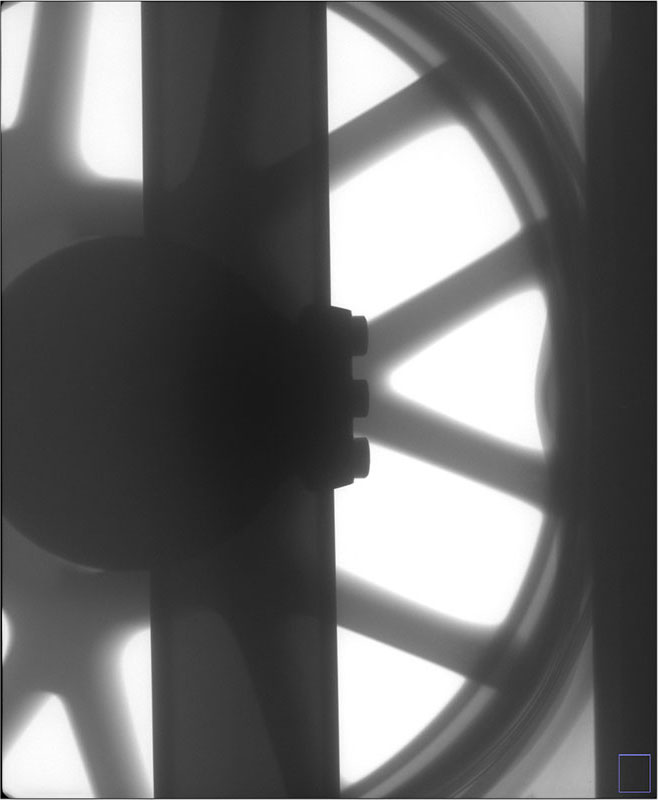

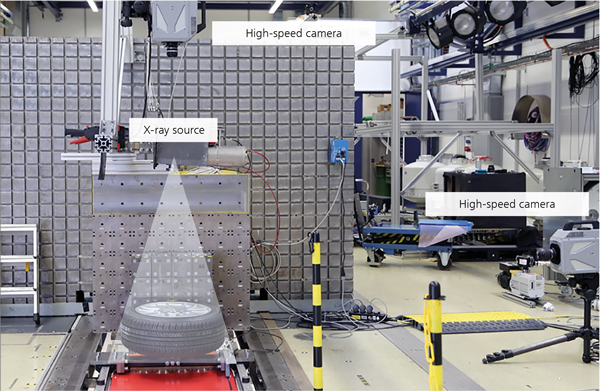

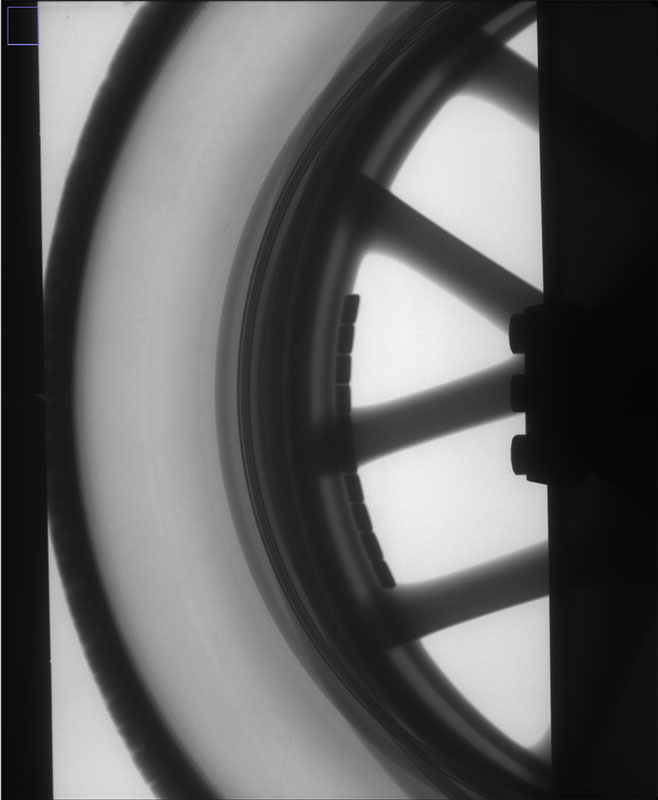

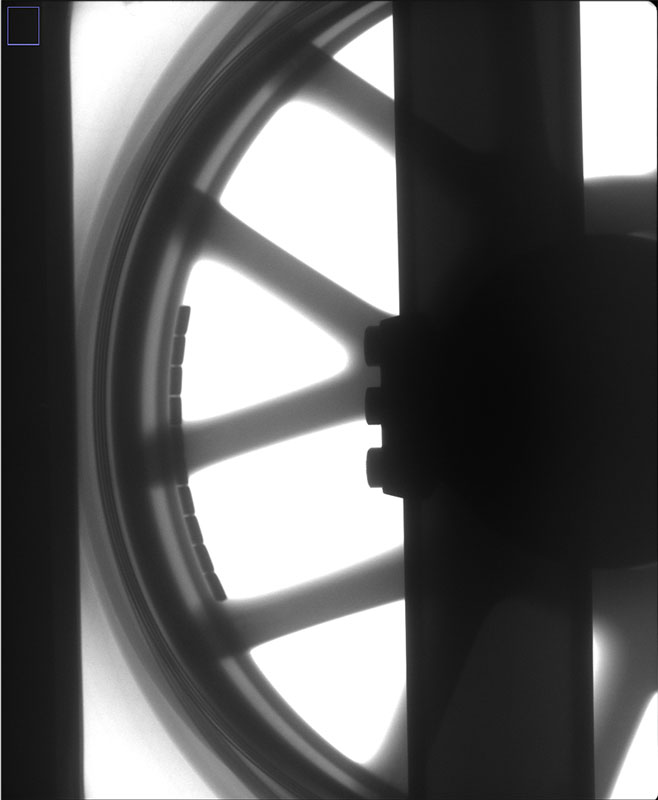

For Benjamin Schütz, working with X-ray flash technology at the Crash Center was exciting new territory. “It was very exciting and satis-fying for me to conceptualize such an experi-mental setup and then successfully implement the planned tests. This gave me the oppor-tunity to gain many new insights and to grow from them personally.” The work builds upon existing know-how at Fraunhofer EMI. Simulations of vehicle wheels have already been carried out at Fraunhofer EMI by Yann Leost. Based on these former simulations, the frame-work conditions of the test rig were defined in such a way that the results of the crash tests are comparable with the simulations. The new feature is the instrumentation with X-ray flash technology.As shown in the photo, the experimental setup includes two high-speed cameras that take images from above and from the side, and an X-ray source that x-rays from top to bottom. At present, it is possible at EMI to take up to eight X-ray exposures during one test with the aid of the multi-anode tube. The linear acceler-ator Linac has been put into operation by now. In the new Linac laboratory LiLa as an extension of the Crash Center, the team can also observe and document such processes via X-ray video at one kilohertz.Link to the video of the third, destructive, test. Here you can see how the tire and rim flange deform, how the air escapes from the tire and how two pieces of the rim break off.