X-ray diagnostics in crash tests picks up speed

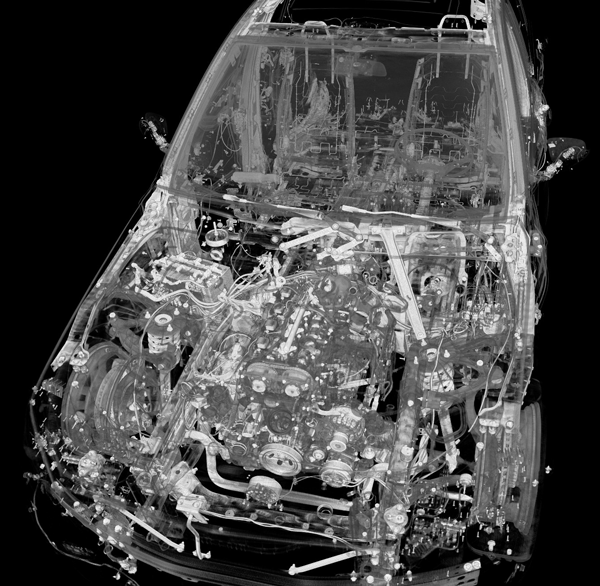

Fraunhofer EMI has been researching the potential of X-ray diagnostics in crash tests using the new X-ray car-crash (X-CC) technology at the Crash Center of the Fraunhofer-Gesellschaft since 2016. X-raying is an established material research technology, which in the industrial sector has thus far been restricted primarily to static and quasistatic analyses. With the X-CC technology, Fraunhofer EMI combines X-ray technology with highly dynamic deformation processes under crash conditions and thereby contributes to the overall understanding of the behavior of inner car structures during a crash. The results are included into the simulation for the optimization of structures, structural components or materials. The long-term goal is to obtain an X-ray video of the crash tests. This business branch of Fraunhofer EMI, which has developed into a large, successful research field, has sparked growing interest in industry and research. EMI develops new methods, simulations and fields of application, conducts industrial projects for notable clients and plans the continuous development of test setups for future studies.

Successful completion of various industry projects

As part of the Tech Center i-protect, Fraunhofer EMI inspected the application of X-ray technology in crash tests in collaboration with Daimler AG with the goal to make safety-related inner structural components of a vehicle visible, even during a crash test, and to combine them with computer-based simulation models in order to improve the predictive reliability of crash simulations. The project began in January 2016 and was successfully completed in 2018.

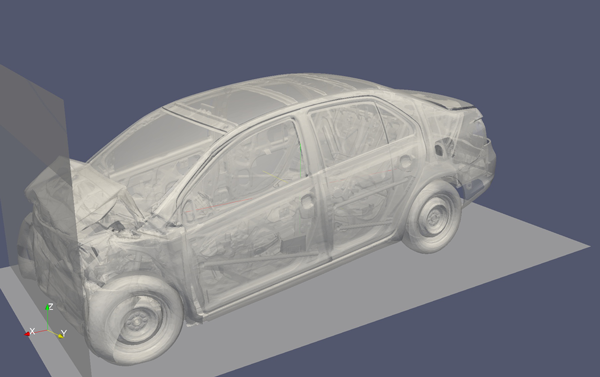

The focus of another industry project was on the experimental analysis of structural components using X-ray technology. With the additional use of a 3D high-speed scanner, the X-ray images could be spatially oriented, and a time-resolved model of the test data could be generated. The scanner was developed by Fraunhofer EMI in collaboration with Fraunhofer IOF and Fraunhofer SCAI and successfully implemented as part of the industry project. The application of this tool is an important step towards the combination of different technologies in the simulation. A third industry project dealt with the improvement of X-ray simulations for experimental designs as well as the assessment strategy, including the necessary algorithms. This project was also successfully completed this year.