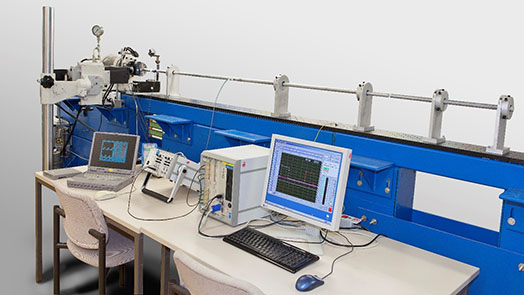

Material testing under high strain rates

To examine the material behavior of, e.g., fiber-reinforced composites or metals, Fraunhofer EMI not only operates servo-hydraulic testing machines for the range of medium-dynamic velocities, but also uses test setups for the characterization under higher strain rates. When employing split Hopkinson bars, long rods create a mechanical wave within the specimens. We dispose of experiment setups for testing pressure loadings (split Hopkinson pressure bars SHPB) and for testing tensile loadings (split Hopkinson tension bars SHTB). As an advantage of these procedures, no big masses have to be accelerated. Depending of the specimen geometry, strain rates between 200 s-1und 3000 s-1 can be reached. For pressure loadings, we utilize, among others, a specifically modified SHPB for the testing of low-impedance materials (e.g., rubber, adhesives). The strain measurement is conducted with optical measurement procedures. By means of specific temperature chambers, experiments can also be performed at increased temperatures.

More on the topic of Split Hopkison Bar testing at Fraunhofer EMI (German)