Material testing under highest strain rates

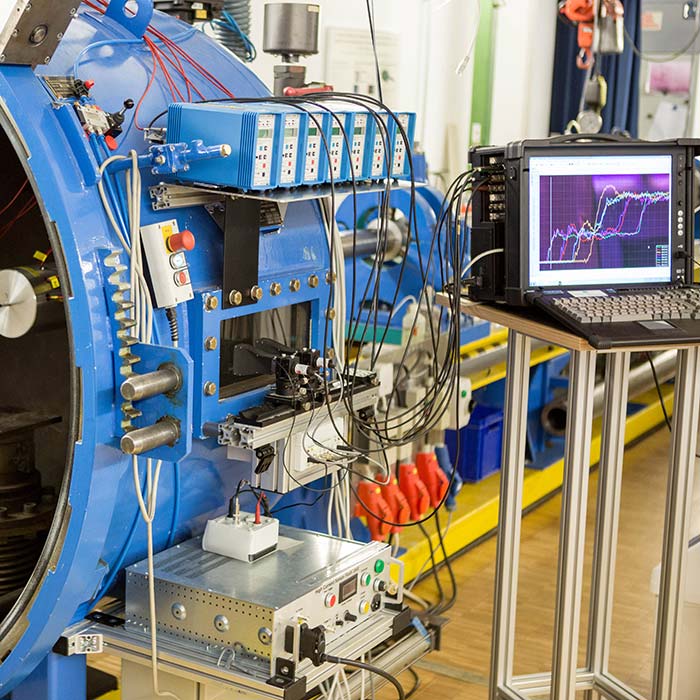

High-dynamic material tests are necessary for the understanding of the material behavior under dynamic loads. Examples are given by car-crash situations, ballistic processes, fast machining or impacts of micrometeorites onto satellites in the orbit. Fraunhofer EMI offers two well-established tests within the field of high-dynamic material research (shock physics) that are unique in this form in Germany: the modified Taylor impact test (MTT) with rod-like specimens and the planar plate impact test (PPI) for which plate-shaped specimens are used.

These tests create well-defined states of stress under highest possible strain rates and enable the determination of material properties which can be used directly for simulation purposes of materials and components. Taylor impact and PPI experiments are very rare tests in the field of dynamic material testing, both have developed into internationally accepted and mature dynamic material tests during the last decades. With these tests, material investigations are extended to strain rates that are significantly higher than in Hopkinson bar tests. Both tests are executed as impact tests, in which planar targets are impacted by a planar projectile with known impact velocity. The impact process creates elastic and plastic waves in the specimen, which in turn induce the dynamic load to the specimen. The effects of the wave propagation upon the back surface of the specimen can be measured using an optical interferometer (“velocity interferometer system for any reflecting surface”, VISAR) with the accuracy of a nanosecond. The velocity-time-dependency (“free surface velocity”) is material specific; from characteristic parts of the velocity-over-time curve, dynamic material properties, such as the dynamic yield strength, the strain and the strain rate, can be derived. PPI experiments can provide further data, as it is needed, for example, for the calibration of equations of state (EOS).

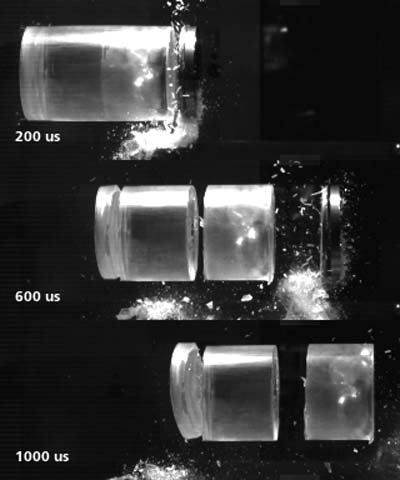

Since the optical method described above is contact-free, the specimens are not affected during the measurement. Normally, the determination of the dynamic material data is done at and for a single point of the specimen, nevertheless, measurements at several points are possible in parallel which helps to determine locally different material properties. Experiments are usually conducted at room temperature whereas experiments with cooling or heating devices are also possible without any constraints. Experiments can be supplemented by high-speed photographs or videos. Samples or sample fragments can be captured safely after impact for further microscopic analysis.