Fraunhofer EMI is researching how new wing coatings can increase resistance to rain, sand and hail damage while reducing fuel consumption.

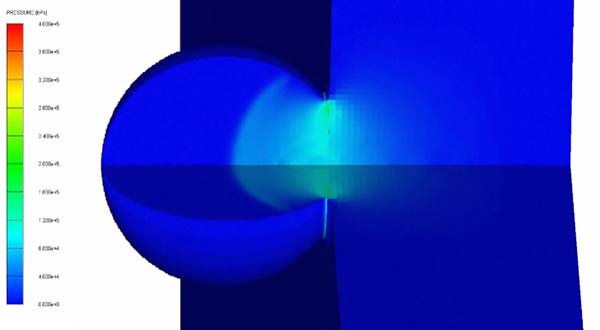

The UP Wing (Ultra Performance Wing) project is part of the “Clean Aviation” research program funded by the European Union. In UP Wing, an interdisciplinary consortium of industry, research institutes and universities is developing important basic technologies for wing concepts with maximum performance for short and medium-haul aircraft. The aim is to significantly reduce fuel consumption. Together with IFAM, which is responsible for Fraunhofer, EMI is involved in two sub-projects in which the resistance of new coatings to rain and sand erosion and the robustness of a new wing structure against hailstorms are being investigated. In the area of rain and sand erosion, EMI is using its expertise in the numerical simulation of impact processes and fluid-structure coupling. Hail impact is to be investigated both in simulation and in impact tests on demonstrator structures.

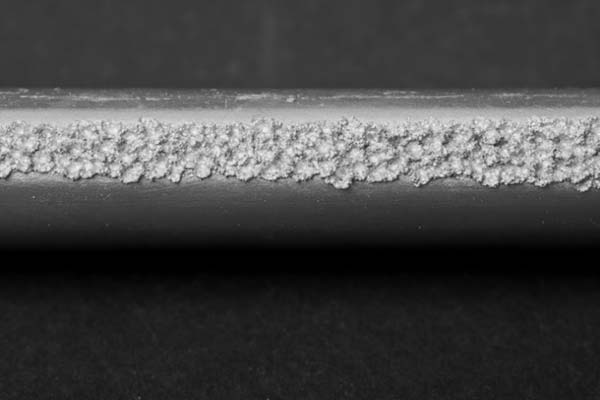

The simulation methodology is currently being expanded in order to be able to simulate the effect of a larger number of impacts. The formation of craters requires a fluid-structure interaction for strongly changing surfaces, which can be realized particularly efficiently for three-dimensional simulations in the EMI software APOLLO by coupling it with a structure solver. This allows the amplification effect caused by the change in geometry to be taken into account. Such models can be used to investigate the influences of material properties and coatings in detail. These investigations support the development of new, fuel-saving and durable coatings.