Vehicle safety: First public X-ray crash test

Researchers at the Fraunhofer Institute for High-Speed Dynamics EMI use X-ray diagnostics in crash tests to visualise the behaviour of internal structures during an impact. At the 5th Dummy Crash Test Conference in Münster, 2 - 3 July 2025, they presented the first public X-ray crash test.

A crash lasts only 0.1 seconds, but the consequences are often severe. Even at 27 km/h, serious or fatal injuries can occur, as the impact forces act directly on the occupants while vehicle parts deform. For decades, industry and research have been working to increase the safety of occupants. This also includes understanding the complex processes inside a vehicle during a crash.

The Fraunhofer Institute for High-Speed-Dynamics EMI uses the X-CC method (X-ray-Car Crash) for this purpose — a short-term X-ray technology that makes high-dynamic deformation processes visible under crash conditions. At the Dummy Crash Test Conference, Fraunhofer researchers publicly demonstrated the creation of such X-ray images for the first time. In a live test, a car collided with a pole at a speed of 27 km/h. The X-ray images showed how the vehicle structures deformed and how and when the internal structures interacted.

Unique in the world: 1,000 X-ray images per second

The X-ray technology of Fraunhofer EMI is unique worldwide: In the institute's crash center in Efringen-Kirchen, southern Germany, researchers can examine complete vehicles with 1,000 X-ray images per second. The recordings show in real-time how cross members or A-pillars deform under load, when weld seams or adhesive bonds give way, how airbags deploy, or how batteries in electric vehicles respond.

A crucial factor for the success of this technology is the powerful linear accelerator with 1 kHz technology as the radiation source. It generates X-rays with a photon energy of up to nine mega-electronvolts (MeV). These rays penetrate thick and dense materials like metal but can also image thin and lightweight components. The high energy is essential for the quality and detail accuracy of the X-ray images. The X-ray pulse lasts only a few microseconds, allowing deformation processes in the crash test to be recorded without motion blur. During the crash test, the X-rays penetrate the body and the dummy models. A detector beneath the vehicle captures the radiation and creates digital images.

»With this technology, we have significantly improved the analysis and understanding of crashes« says Dr. Malte Kurfiß, head of the crash center at Fraunhofer EMI. »The ability to capture X-ray images in real-time helps development engineers in the automotive industry and battery manufacturers make their products even safer.«

Innovative X-ray technology in crash research

Fraunhofer EMI has been researching the potential of X-ray diagnostics in crash tests with X-ray-Car-Crash technology (X-CC) for nearly ten years. In this process, scientists combine X-rays with high-dynamic deformation processes under crash conditions. The results are integrated into simulations for optimizing structures, components, or materials.

X-ray is an established technology in materials research, but in the industrial sector, it has so far been primarily limited to static and quasi-static investigations.

Press photos for download

A crash lasts only 0.1 seconds. The short-term X-ray technology of Fraunhofer EMI makes the complex processes inside the vehicle visible.

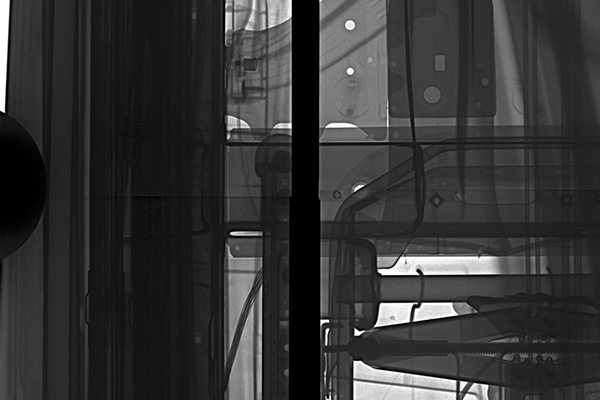

X-ray image of the vehicle interior before the crash.

Insights into crash dynamics: The X-ray image shows the deformations inside the vehicle 70 milliseconds after the impact.