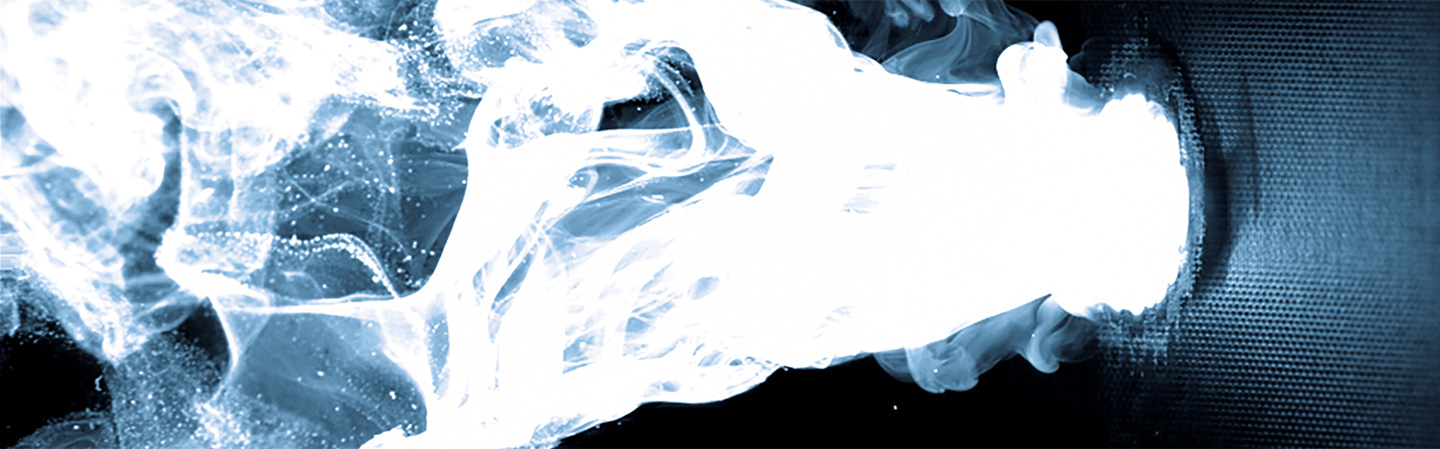

Industrial 3D printing system for additive manufacturing of large metal parts at Fraunhofer EMI

This manufacturing system for 3D printing allows the production of large metal parts with a building volume of up to 400 x 400 x 400 cubic millimeters at a laser power of one kilowatt. These characteristics make it one of the largest high-perfomance and commercially available facilities for the laser-sintering process. Regarding its deployment for research purposes, this size is even unique.